If your headed to Indonesia then this post should be of interest.

We rarely anchored in deep water before we went cruising full time

and headed off to distant shores. When we cruised the East Coast we

thought ten metres was deep water and tried to avoid anchoring in any

thing much deeper than five or six metres. There was a couple of

times we did anchor in ten metres but it wasn't often. We would

easily and often anchor in five, this depth would allow the tide to

run out two metres and still leave us with a meter under the keel at

low tide.

|

| Not how you want to begin the day. |

When we were

getting ready to head off to SE Asia we were bombarded by different

views on how to anchor in the deeper water. One couple that had done

several trips into Asia would give out advice to anyone who would

listen. After talking with them briefly about anchoring we started to

doubt our preparation, we began to think we didn’t have enough

rode or for that matter how could we actually carry enough. We really

don't know how this couple anchored exactly, what we do know is they

carried an extremely long length of chain. We later found out this chain was

smaller in diameter than our own, and they had an old generation anchor on the end of it. We can only assume they

carried extra length of smaller chain and tried to maintain the scope

mantra often repeated in online forums, training courses and yacht

club bars.

Fortunately we ran

into other couples who had done several trips in SE Asia and they

explained that one hundred metres of chain is more than enough and we

shouldn’t worry at all. They went on to explain that in the deeper

water we can start to rethink the ratios we are consistently told

work and start to properly use the catenary effect of the chain.

Anchoring in deeper water really calls for a different approach to

the rode, depth, scope ratio’s we have all heard so much about. One

of the couples had anchored in thirty metres regularly when they

explored the eastern islands of the Indonesian archipelago.

For us anchoring in

shallower water had been the norm, we had been using snubbers for

some time and had worked out an easy to use system. We had been in

some serious storms at anchor and could see the chain pulled taught

while the snubber absorbed the energy generated by the snatch loads

this reduced the chance of damaging the vessel, breaking the chain or

dislodging the anchor. We saw time and time again that when anchoring

in shallower water it didn’t take much of a storm or increase in

wind strength to pull the anchor chain straight and taught. This is

mainly due to the lack of depth not allowing enough length of chain to hang into deep water to develop and maintain the required curve for

the catenary effect absorbing the shock loads on the anchor.

To anchor in deeper

water was not going to be as tricky as we first thought. However it

is a whole anchoring system not just the anchor and chain.

Now I have said

that, the first thing I am going to discuss is the Anchors.

Anchors

Size does matter! and the bigger the anchor you can fit on the bow of

your vessel the better. Look at the selection chart for the anchor

you have and compare it to the other manufactures charts. You are

likely to find most anchor manufactures will recommend anchors that

are too light for the size of the vessel. I am lead to believe this

is a marketing ploy to stay competitive with other manufactures who also under size the recommended anchors. If a

recommended size anchor is cheaper for a given size of vessel, they

are more than likely to sell more anchors, and the way I think it

works is when boat builders fit out new yachts, they are looking to

reduce costs. They will purchase the size recommended by the anchor

manufacturer, not the size recommended by the cruising community, who

know from experience the recommended anchors are too small for anything other than a picnic stop for lunch on a calm day.

I could go on and explain the benefits of the new generation anchors,

giving a break down of brands and types but I won’t as I have found

it causes to much friction, people have a habit of defending even their worst purchase choices.

What I do know from experience is, the

new generation anchors work better. We should also know from

extensive testing by yachting magazines, private individuals and even

company sponsored anchor testing the new generation anchors out

perform the older generation anchors on just about all points of the tests. Yes I know every now or then one of the old generation anchors does come up and surprises all the testers, however it's rarely consistently repeated.

So the best thing to say is when purchasing an anchor, get one of the

new generation anchors. Look carefully at the sizing guides to get an

average weight for an anchor to suit your vessel. Discard any guides

that recommend remarkably lightweight anchors through the range then

go up 2 sizes and you should have an anchor that allows you to stay

put when the wind comes up in the middle of the night. Another thing

to look for in the test data is a common thread, if an anchors

holding power is low → medium more times than it is high (even though it's advertised as "Lloyd's listed as High Holding")I would

give it a miss.

Reality check: High holding is ok however in the cold of night an anchor with super high holding rating certainly helps soothe the nerves when the wind comes up.

Snubber’s

We have found a

snubber is a vital component of the anchoring system if you use all

chain rode. A snubber is a length of strong but stretchy rope

(nylon) anything from 5 to 15 meters long, one end attaches to the

anchor chain as the last of the chain is deployed and the other end

tied round the bow mooring cleat. We have seen all manor of snubber’s

in our travels and unfortunately a lot would not do what they are

supposed to do.

Snubber's are best

made of nylon because it stretches and is strong, it has good UV

protection, will work wet, is easy on the hands when handling and is

easily spliced. To have an idea how big a diameter you need

requires experimentation. Start by looking at what wind strength

your anchor chain starts to become straight, (every vessel is different) its at this wind speed

you want the snubber to be adsorbing the energy from the vessel

movements. On our vessel we use a long snubber that is two

millimetres smaller than the recommended anchor rope diameter. There

is no magic bullet with one size fits all when it comes to snubber’s,

there are so many variables and a decision must be arrived at for the

individual vessel. Things that will ultimately decide the length and

diameter will include vessel windage, displacement, chain size

(weight) and anchoring points. I recently read in an online forum

where there are some who use mooring micro snubber’s and mooring

lines, unfortunately for them nothing good can come from these

setups. Mooring lines and equipment isn't made for anchoring and has

the potential to be disastrous.

The amount of

stretch is directly proportional to length.

• A 8m long

snubber can stretch twice as much as a 4m long snubber.

Or inversely

proportional to the square of the diameter.

• A 10mm diameter

snubber can stretch twice as much as a 14mm diameter snubber.

As an example a 12mm diameter nylon snubber when new (breaking

strain 3000kg) has about the same breaking strength as 8mm Grade L

chain (3272kg breaking strain)

|

| Testing a new snubber @30 Knots in shallow anchorage the chain has straightened out |

A smaller diameter nylon snubber is strong enough to add the

required stretch in the system, however a large diameter snubber or

a snubber made of the wrong material totally defeats its intended

purpose. I have heard catamaran owners happily telling others they

have an oversized or ruggedly constructed bridle for anchoring. While

this sounds great in theory, in practice this will only add to the

grief of having problems when anchoring. Without incorporating a

springer into the bridle there will certainly not be enough energy

absorbed due to the boat moving when the weather comes up. If the ruggedly constructed bridle has limited stretch the only thing that's going to happen is the anchor will be slowly dislodged one little shock load at a time.

|

| We attach our snubber to our anchor chain with a Dyneema loop, makes it easy quick and light weight. The best thing is its easy to go through the bow roller and doesn't fall off when you need it most as the boat starts to move about. |

|

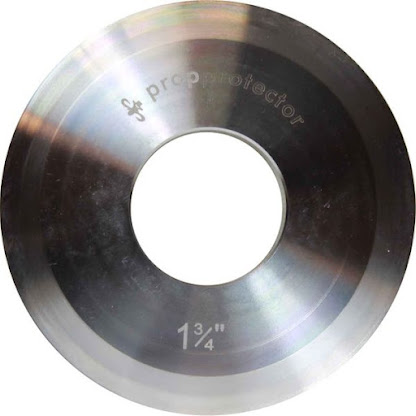

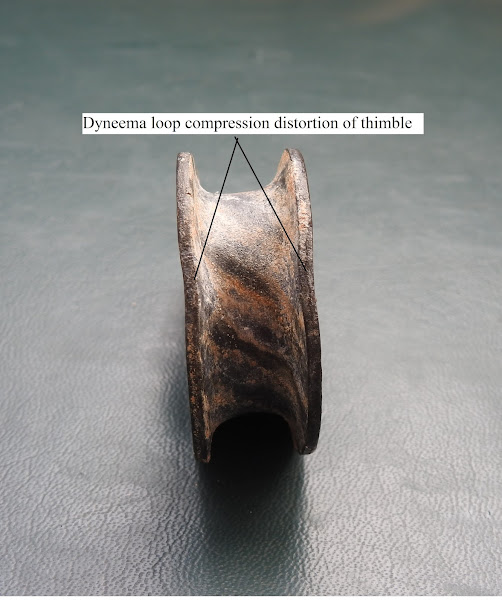

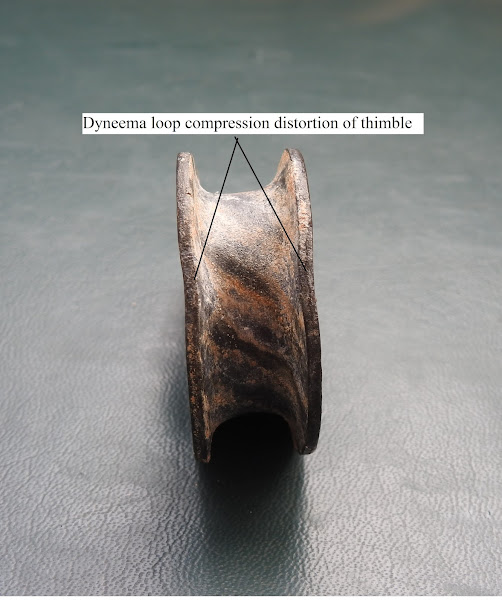

| Use better solid thimbles in the snubber (top), the standard thimbles can distort badly and fail under high storm loads (as we found out) |

|

| Snubber to chain connection, only takes as long to attach as doing up a button and doesn't fall off, and can be made onboard if you have the raw materials, Dyneema cord and 5 minutes of time. |

Galvanised Anchor

Chain

Selecting the right

type of chain can be very confusing due to different grading systems.

There are a variety of link sizes and the best thing to do is take

your chain capstan with you when you do make the final decision on

the chain supplier. Make sure the chain is a perfect fit into the

capstan and does not bind when the chain rotated through it.

Is it better to have

a long length of high strength light chain or a shorter or same

length of lower strength heavy chain? Both have energy absorption, so

there is not much point in using high strength chain as it corrodes

quicker and can actually be brittle, which can cause handling

problems. When its all said and done it is certainly best to use a

long length of heavy chain!

We get by with 110m

of chain, and I don't remember there is any time we thought we needed any

more. We do however keep a 100m coil of nylon and 30m of chain as

back up in the locker, but have only used some of the rope when it

was time to cut off several metres for various jobs.

Anchor Chain

Storage

In a lot of

anchorages the bottom is sand, broken coral, mud (some times putrid)

and or a deep layer of the ever present plastic bag so have a

pressure saltwater wash down hose, you may have real problems if you

rely on a bucket on a string. We know of one cruiser who ended up

with several kilograms of putrid mud in the anchor locker due to blocked

drains that required him to deploy all his chain, clear the drains

while washing out the mud. What we found is that plastic bags or pieces come up in the mud from the chain or anchor and it doesn't take much for a piece to block the locker drain.

Anchoring In Deep

Water

You can pretty much

throw out the old scope ratios we have all read about in the sacred

texts that were written by the ancient mariners. So for example if we were to go with the standard 5:1 that is

used in shallower water. Enough chain to obtain the 5:1 chain to

depth ratio in 25 metres of water is going to require 125 metres of

chain, and if sticking to the convention even more if the weather is

coming up.

So now on to

something we used successfully. This will really only work if you can

anchor successfully in shallower water. If your vessel usually skates

off when the breeze comes up then this won't be a fix, and you are

likely to still skate off on the breeze. Every one we talked to who

had successfully used this technique had a new generation anchor, but

that's not to say it won't work with older styles of anchor. Some who

were unsuccessful did also have trouble anchoring in shallower water,

and with out being to specific it was usually a combination of

problems. These included under sized chain, undersized or old

generation anchor or both, poor use of snubber or not using a snubber

at all.

What technique

worked for us: Lay out 20 metres of chain and then lay out a length

double the depth and don’t forget to use a good elastic nylon

springer (minimum of 6 metres long), if its a bit windy or you

require a little more security add another 10 - 20 metres of chain.

So if anchoring in 20 metres lay out 60-80 metres of chain. If your

really worried, let out all your anchor chain from the locker.

While this twenty metres and a length double the depth doesn't sound

like enough, due to several factors you will find it should be. Keep in mind if your securing the snubber to the mooring

cleat at deck level of the bow roller then allow for this, deploy

extra chain double the distance from water to the bow roller.

|

| Water Depth Catenary chart |

How does it work: In

the deeper water the chain is allowed to hang into the depths. There

is a lot more weight of chain suspended in water and now the catenary

effect is very effective at absorbing the energy created when the

boat is moving. Where as in the shallower water it doesn't take much

additional wind to make the chain straighten out. When the chain

straightens out there is very limited (or no) energy absorption, and this

allows any vessel movement to be transferred directly to the anchor

and the vessels cleats. This additional load from the increased wind

strength and movement of the vessel due to wave movement creates high

shock loads which can quickly dislodge the anchor or damage the boat.

You can have the

best technique, and be anchored nice and snug in deep water,

however if the wind turns and the fetch allows a large swell to roll

into the anchorage all this work can come undone. We had this happen

on occasions during the monsoon transition months, or a Sumatra winds coming in at O'Dark Thirty, always

have a plan B mapped out.

We also anchored in very deep water where it went from the shore to 40 metres in three to four boat lengths, while this sounds crazy we would set up a stern line to shore and then drop the anchor out in 50 plus metres, then back down while bringing in the stern line. We found that even with a steep sloping bottom the anchor would dig in and wouldn't budge. Having the stern line stopped the boat swinging and pulling the anchor out into the deeper water. Even still it did give us an uneasy feeling looking out the back and feeling like we could just step out onto the shore.

Below is an excerpt from Rocna Anchors site, and while I am not

advertising them, I believe this to be a good description of the

definition of old generation anchors.

Old generation

anchors include most types and designs dating before the Bügel

(1986) and Delta (1990). Because the Bügel uses what we consider to

be some new generation design characteristics whereas the Delta is

first and foremost a plow, these two types define a bit of an overlap

between the 'old' and 'new' generations which marks the transition

from old to new on the timeline.

Below is the remains

of our snubber after being caught on a lee shore with three nasty

storm fronts coming in unannounced at O'Dark Thirty with the South

China Sea as fetch. While we weren't anchored in deep water, I have

put it in for reference, and why it's important to use high spec gear

in the anchor system, and an example of how a simple Dyneema loop can

hold fast.

|

| This is how well the Dyneema Loop holds on, this thimble was at the anchor chain end and held on until the snubber became so over worked it melted and then parted. |

|

| What remains of a well used snubber, while its not easy to see the snubber worked so hard during the storm the core is fused together from friction. Interesting evenings entertainment, three storm fronts came in at O'Dark Thirty and had us pinned on a lee shore until we were able to pull the anchor up and get out of there. The snubber parting happened shortly before getting underway. |

|

| Back end shot of the distorted thimble. We now source heavier duty thimbles for use in our anchoring system. |

I am not promoting these anchors and I don't want to upset people however here is a link to Yachting Monthly with a short list of New Generation Anchors, and there isn't a Plow or Delter to be seen. I have worked in the marine industry for over 20 years and lived aboard for 13 years and have sailed most of my life. I've had my fair share of old generation anchors. One such incident sticks in my mind when anchored in a bay with good holding, we woke when the wind came up, I was searching for my trousers while Deb was looking out the portlight saying all the boats in the anchorage are all leaving at once. It took a moment for what she said to make sence, they weren't leaving we were going backward through the anchored boats at speed, quick start the engine!!!.