For many years my job had me installing all manner of marine electrics and electronics in vessels located at different ports around the world. I didn’t think that purchasing the right size wire, terminals and tools to do electrical work on my vessel back here in Australia would be very difficult. However, I thought wrong, as I found out it’s not a simple task for the average cruiser to get all the right equipment together. When I was preparing to do upgrades I didn’t realize that I was about to go on a steep learning curve. I knew what I wanted from measuring the cable runs and then doing the voltage drop calculations. I simply thought I could write out a shopping list and go along to the chandlery or auto/electrical supply store and get what I wanted. Unfortunately due to the way wire is marketed here in Australia purchasing wire requires greater care, but more on that later. The flow on effect of differing gauge can mean it’s easy to make mistakes and use undersized wire or perhaps crimp on terminals meant for larger gauge wire.

A lot of the easily accessible information on line or in books is for equipment and materials manufactured and marketed overseas. The same can be said for the information supplied by company’s making wire, terminals, tools and marine components. Perhaps it’s also a sign of the times where most of our tools are imported and it appears they have been manufactured for sale in a global market place so at times they are not an exact fit to products produced here. This does not make it easy when we head off to the chandlery to purchase bits and pieces to do an install or repair job. So as I collected information I assembled this assortment of cross referencing information into a format that I hope will make it easier for us to get our head around. I know most sailors will head off to the local chandler when they need marine wire. With that in mind I have tried to incorporate the most commonly stocked wire sizes into the calculations for current handling and crimp terminal sizes.

As the electrics on the average cruising boat become more advanced the one thing that has always been a requirement for reliable operation is the need for electrical installation or repair work to be done neatly and efficiently. To do this correctly you will need to plan the job, have the right tools, wire and the correct terminal fittings. It doesn’t matter whether you’re installing new electronics, electrical gear or rewiring something already on board, the necessities for safe, dependable and secure electrical connections are the same, do it right the first time, using the correct gear.

Planning the job will save you a lot of hair pulling later. Take time and explore your options to decide how the new equipment will be installed. The plan should include where the equipment will be installed, what interfaces to the equipment and is access to the newly installed equipment reasonably easy. Where is power to the equipment going to be run from and how many amps are required? These are a very important questions that will need answers for proper installation.

Only you can really decide where the equipment will be finally installed. Then once that’s done the next important consideration is the length of the cable run. Not just an as the crow flies type of measurement but take all the curves and up and around and through cabinets and cable trunks type of measurement. By taking current draw (Amps) and cable length into the calculations the correct size wire can be purchased and run. But don’t buy cable just big enough for the job, you don’t want the wire to be running at one hundred percent of current carrying capacity. Go the next size up for redundancy and remember the bigger the wire the less resistance it will offer a load and the easier electricity will pass through it, and the cooler it will run. A win win situation for all.

I have mentioned safe electrical installation, keep in mind several vessels are lost each year due to electrical faults. If doing electrical isn’t your forte then before applying power it could be worthwhile to have a friend to look over the job before you throw the switch.

Wire Gauge

The term wire gauge refers to the conductor cross sectional area of a wire. Wire gauge can be used in calculations to determine electrical resistance and the current handling capability.

In Australia there are several means of describing wire gauge for wire used on recreational vessels, the most common are Trade Cable Diameter, MWG (Metric Wire Gauge), AWG (American Wire Gauge), and B&S (Brown & Sharpe). B&S is equal to AWG. B&S has been commonly miss quoted as battery and starter, or perhaps this label is used to sell a product that is not sized correctly.

Trade Cable Diameter is commonly used to market automotive/marine wire in Australia. This is a trade unit referring to the total diameter of the cable to the outside of the insulation, closer investigation is needed to find the cross sectional area of the wire conductor before calculations for current carrying capacity can be carried out. We will mostly need to convert from Trade Cable Diameter to MWG (Metric wire gauge) which measures the cross sectional area of the conductor in mm². Metric wire gauge is used in several countries outside of the United States.

|

| Good quality cable stamped with size temp rating and maximum voltage |

AWG (American wire gauge) is most commonly used in the United States and because of the size of the market, manufactures all over the world compete and manufacture goods to their specifications for sale on that market. One thing that is usually evident with wire made for the American market is; that in most cases the size of the conductor and the temp rating of the insulation is stamped on the jacket of good quality marine cable and wires. The AWG is determined by the cross sectional area of the conductor and doesn’t include the insulation, the same as MWG however AWG is described using a list of defined standardized gauge numbers. AWG gauge numbers work in the opposite direction to MWG, with the smallest numbers representing the largest diameter wires. For example 6mm Trade Cable Diameter has wire with a cross sectional area of 4.59mm² (MWG) and this is roughly equivalent but on the small side to 10 AWG. The next popular size on sale at the chandlery is 4mm Trade Cable Diameter, this has a conductor size of 1.84mm² MWG and is equivalent to 15 AWG.

B&S is commonly used for marketing heavier wires and cables in Australia, I guess this is where the confusion and tie up with batteries and starter came about. As mentioned earlier B&S follows the same gauge descriptions as AWG and is simply another way of explaining the wire gauge. As an example 2 AWG = 2 B&S, 4 AWG = 4 B&S and so on.

Wire

As we know wire could hardly find a more unforgiving environment than on board a yacht. On board wiring has to be able to deal with the high humidity and consistent vibration, and be able to recover from the odd submersion as well as heat and cold from all manner of sources.

Wire used on a boat must be copper, though even copper has been known to corrode in the harsh marine environment. The most common cause of electrical wire failures is primarily corrosion and secondly poor work practices installing terminals and wires. I am sure we have all heard of tinned copper wire and we will need to pay more for the advantage of having the wires tinned during the manufacturing process. Tin plating each of the multiple strands of the wire with a coat of tin dramatically improves corrosion resistance. The additional cost of tinned wire is worth every additional cent because the anti-corrosion benefits are substantial. While the cost savings of buying untinned wire in the auto electrical section of the car parts supplier looks tempting, try not to justify this false economy. The cost savings are usually short lived due to the high failure rate of untinned wire.

Choose your wire carefully. Never use solid wire or wire intended for wiring a house. Vibrations will eventually fracture solid wire. It doesn’t need to be high frequency vibrations, wave motion is enough to flex all the wires on the vessel even if you don’t feel the movement. Boat wiring must have the flexibility multiple fine strands provides. The insulation covering the wire used in house construction is different to cable intended for the marine industry, so this is another reason not to use house wire on the vessel. Marine cable uses heavy tin plated annealed copper wire formed in such a way as to reduce capillary action of moisture within the cable. The flexible stranding (multiple fine strands) helps withstand fracturing due to the movement caused by the marine environment. Good quality marine cable has high temperature insulation to withstand the high ambient temperatures of enclosed engine bays. Depending on the brand some offer V75 (75 degrees C) and I have seen other suppliers/manufactures who market V95 cable. Where is your cable going to run? If it’s through the engine bay wire with the higher temperature rating specification could be the better option. Don’t use wire in an engine bay if you have no idea of the temperature rating of the cable insulation jacket, it’s just asking for trouble.

Most work for rewiring or installations will require two wires one positive and a ground (return) of the same size, don’t fall into the trap of believing the return wire size is insignificant, its size has to be equal to the supply wire. Twin sheath wire where the twin red (positive) and black (ground) conductors are encased in a second layer of insulation. This is convenient and provides the added safety of that second layer of insulation. There is also imported twin sheath wire with red and yellow conductor insulation, this is usually wire made for the American market due to their marine colour code where the black insulation colour is the active wire in an AC circuit. There is single wires and a three core wire for use on extra low voltage work on board, the wire colours vary with supplier but white, brown and yellow is common.

Size

As discussed earlier, wire sizing in Australia isn’t easy for the average yachty to get their head around the way wire is marketed. Unfortunately this mish mash of labeling requires careful investigation of the product to ensure it meets the correct size specification for your application before handing over your hard earned money.

The bigger the wire is the easier electrical current will flow through it. Some voltage will be used up pushing the current through the wire. This loss, called voltage drop, should not exceed 3%, for most circuits. However there is some equipment that won’t mind a slightly lower voltage, the only way you will know this fact is to look at the equipment specifications sheet supplied with your equipment. It is essential to use wire sized for the maximum current flow you expect it to carry. If the wire supplies a single unit, the current requirements will be shown on the label on the unit, or in the installation/owner’s manual. While a 3% voltage drop sounds like it would be easy to achieve remember 3% of 12.6 Volts is a drop of .38 Volts. So the voltage at the other end of the wire at the appliance when running under full load should be at a minimum 12.2 Volts.

To arrive at the length of wire used in the calculations for the correct size wiring, you need the wire length from the power source (circuit breaker) to the unit and back to the power source. As explained earlier not just a as the crow flies type of measurement. You must determine the actual length of the wire by measuring along the path it will follow-up down, over, and around. I have found in most cases that it’s not unusual for a wire run to be more than double the as the crow flies distance.

Not all (I haven’t come across any) electrical wire made to Australian standards as appropriate for marine use will have the gauge designation and temperature rating printed on the insulation, on the reel yes but not the cable its self. Perhaps the Australian standards and the manufactures need a kick start, this is a really poor/bad state of affairs. You will find that the best thing to do is to label the wire after purchase so it does not cause confusion at a later date. If you have purchased imported wire remember the smaller the gauge number, the larger the wire diameter.

|

| Australian Manufactured Wire. A mystery once off the reel. No identification for size or temp value only a mark where the retailer should cut metre length markers |

When purchasing wire for a job, buy wire at least a six hundred millimeters longer than your measurement. You can easily shorten the wire after it is run but lengthening requires a splice. Each wire should be a single continuous run between terminals, this helps keep the moisture out of the cable length.

When you do your calculations and head off to the chandler to buy the wire for your job, beware of the misleading marketing used to sell wire. Some rolls of cable will have current carrying capacity on the reel or in the store catalog, these calculations don’t come with any information as to the length of the cable run or the voltage drop calculations.

Wire sizing Reference

Table 2 shows what size wire is required to deliver adequate voltage to the other end. Use the maximum current draw of the equipment to select the row and the round trip wire length to select the column. The number where these two intersect is the wire size you need.

I have tried to simplify the wire sizes to the ones commonly held in stock at the chandlers. The numbers with mm (e.g. 6mm) is the normally advertised (Trade Cable Diameter) cable size, this is not the cross sectional area.

Wire sizes without the mm are B&S measurements. Remember B&S = AWG sizes. Cables less than 8 B&S are available in the white twin sheath; cable sizes 8,6,2 B&S are available in a twin with black sheath but not normally stocked in most chandlery’s but should be available so shop around. For better protection when using single layer insulated cables the cables will need to be run in conduit, cable trays, loom tube etc.

In table 2 the Round-Trip takes into account the total wire length (both wires) in the circuit. So an instrument three metres from the power source will at minimum use six metres of wire in the run, three metres of (positive) wire from the circuit breaker to the unit and three metres back to the ground bus to complete the circuit.

The Right Tools

The cost of the tools now days is nominal, however there are some very good trade quality tool out there costing a lot and for very good reason, they are made for day in day out work. For the amount of work most of us do on our vessels I don’t think the out lay would be justified and is more than we need to pay. Beware of clever advertising, I have seen tools that I would say are really poor quality advertised as tradie tools. The slightly better tool with several additional functions are marketed as professional tools. Do your homework before splashing the cash and you should be able to get tools that are easy to use and provide trouble free service. I would even go as far as asking the sales assistant for a demo. Yes I bought a crimp tool that was the be all to end all, what a disappointment when I got it out of the box at home and found I would need handle extensions to make it work. What upset me the most was that I had to pay a restocking fee when I returned a tool that clearly didn’t work.

Wire stripper: We should all have a good quality insulation wire stripper in the tool box. Stripping insulation with an inappropriate tool can result in a nicked conductor; or damage to the insulation. Nicking through the tin coating opens the gate to corrosion at a later date. Or on the other hand if the stripper damages the insulation there is the possibility of this hindering your ability to complete a proper crimp and the flow on result, a compromised join.

|

| Wire struppers for most smaller wire work, with the bigger size cables I use a electricians pocket knife. |

Something to be borne in mind is that strippers sold in auto supply, hardware and tech stores can be for a variety of wire types. To clarify, I mean wire manufactured to the different standards, I have only touched on the most common types. You may find your strippers are marked with SOL and or STR, confusing unless you know that SOL stands for solid wire and STR is short for stranded wire. We should never use solid wire on a boat so buy stranded wire and use the STR marking slot. The next hurdle is going to be whether the strippers are for AWG (American Wire Gauge), or MWG (Metric Wire Gauge) or has the tool been made/marked to be for both. Now the thing here is who did the calculation and did they round up or round down when doing the cross reference. The best thing you can do is once you find a set of strippers you like is to do some test strips to make sure you don’t nick the conductors or reduce the size of the wire by accidently trimming the conductors and mark them up for your use. I found a set that works well and is marked with both AWG and MWG, I still have to be careful when using them to make sure I don’t scrape the tin off several of the conductors but I know they are not going to reduce the size of the conductors by nicking off strands of wire.

The Table 1 has a reference between the different sized wires so selecting the right slot on the stripper can be done easily.

Crimp tool: You absolutely cannot make a dependable crimp connection with a pair of pliers or a set of multi-grips. However reasonably inexpensive (not ratchet) plier type crimpers normally sold for the automotive industry, if used correctly can make satisfactory crimp connections. There are different styles of crimpers, it’s not a one style does all. Some are for insulated terminals only and others feature jaws/dies for insulated terminals and non-insulated terminals. One rule you will need to follow is to know how to use the tool and make a few practice crimps first. However you cannot beat a ratchet crimper, this style of tool offers the advantage of not letting you produce a crimp that does not have the required tension. That is as long as the wire and terminal sizes have been matched correctly. A ratchet crimper offers the benefit of consistency if used correctly. Just so you are aware, having a better tool does not guarantee perfect results every time, but practice first and you will be producing good crimps in no time.

|

| Tools. Top Uninsulated Crimper Middle Insulated Terminal Crimper Bottom Special Connector Uninsulated Crimper |

I could just leave it here as a general piece about crimp tools, but and there always is a but, crimp terminals come in a variety of styles. The problem is recognizing the type of crimp you have so you can match it to the correct tool. Hopefully the next paragraphs will shed some light on the styles and what tool to use.

Terminals

Terminal Styles: insulated, insulated shrink tube, un-insulated, cable lugs and un-insulated specialist connectors.

Insulated terminals can be easily identified by the coloured plastic boot on the end of the terminal. It doesn’t just stop at just a plastic boot however, depending on the brand some have additional tinned copper sleeves under the plastic insulator. The colour of the insulated sleeve on the terminal will denote what size wire the terminal is made for. If you haven’t had a lot of exposure to crimp terminals you may not realize the plastic sleeve serves a couple of purposes. Besides insulation and identification, one important aspect of the sleeve is that in a properly crimped insulated terminal the sleeve acts to relieve the stresses placed on the wire where it exits the insulation jacket. This will stop unnecessary stress on the wire due to vibration or movement when connected to a terminal block, without strain relief the wires may fall off the back of the terminal after a short service life.

Insulated adhesive lined shrink tube terminals are colour coded like their cousins, the difference is the shrink tube is transparent and a larger diameter than the standard insulated terminals. These terminals are not a bad idea on a boat, they offer a level of strain relief not achievable with standard insulated terminals. However they do not create a water tight seal at the end of the cable but they will stop water entering between the wire insulation and the tubing. Greater care will need to be exercised when using shrink tube terminals so the tube is not damaged. A single jaw crimp tool must be used, not the dual jaw/die as would be used with standard insulated terminals. The other way to achieve a heat shrink strain relief is to apply shrink tube over the crimped insulated terminal and shrink it down.

The colour code for the insulated terminals is: Trade size wire MWG

|

| Insulated crimp terminals of various sizes and styles. |

|

| Uninsulated lug the ones shown above have a seam that is easy to see, mostly this style of lug is for smaller diameter wire. |

Uninsulated lugs come in a few different styles, some are made for specific wire sizes and the hole diameters on the ring terminals. When using un-insulated terminals if the crimp barrel has a seam, the crimp indent should be made on the opposite side, mostly the seam is easy to see.

|

| A uninsulated terminal, the indentation from the crimp tool is made on the side opposite the seam as can be seen here. |

|

| Apply solder to the end of the wire to seal the tube and wet the wire inside of the crimped connector |

|

| Uninsulated terminals on a short wire, adhesive lined shrink tube used as a sealant on the connection and doing a double service as strain relief of the join between the wire and terminal |

|

| Uninsulated lugs, heavy duty, the cable size and hole size for the stud is marked on the lugs. In this case in mm² & millimetres |

|

| Specialist uninsulated crimp tool, seen here with the contacts and shell of a multi contact connector housing |

Other terminals are made for use with specialist crimp tools, these terminals are made for plastic boots to be fitted over the cable insulation before crimping the terminal on, then slid over the crimp once finished. These crimp tools can also be used to install the specialist terminals when assembling multiple contact quick connect plugs and housings.

Warning you do get what you pay for

A word of warning you do get what you pay for when crimp terminals are concerned. Terminals sold cheaply at the local electronics enthusiasts or vehicle accessory store may not be a very good choice. In a lot of cases they are not tinned copper but a copper alloy blend, they are hard to crimp both physically and mechanically and in service offer poor corrosion resistance.

Crimping

Strip enough insulation for the wire to reach the end of the barrel of the terminal inside the insulated end. Grip the terminal in the correct crimper slot, fully insert the wire into the terminal. It’s time to eye ball your creation before squeezing the trigger on the crimp tool. Make sure enough wire is inserted into the terminal barrel, if you are using fully insulated terminal and cannot see the end of the wire try the wire for size in an open terminal to be sure. Too much insulation stripped off can be as bad as not enough and could lead to a compromised crimp job. When using insulated terminals no bare wire should protrude out from the terminal. Have another quick look hold the wire into the terminal and squeeze tightly.

|

| Insulation stripped to length to fit the barrel of the connector |

|

| Strip enough insulation for the wire to reach the end of the barrel of the terminal inside the insulated end. |

|

| Grip the terminal in the correct crimper slot, fully insert the wire into the terminal. It’s time to eye ball your creation before squeezing the trigger on the crimp tool. |

|

| Finished crimp the wire has been retained in the crimp and the plastic tube crimped on to the insulation for strain relief on the join. |

As discussed in the terminal section the insulated terminals plastic sleeve will need to be crimped on over the insulation of the wire to add mechanical strength. Insulated terminals are usually installed by a crimp tool with a double jaw/die. If your crimper doesn't have a double crimp jaws, crimp the terminal to the wire first, then reposition the tool and crimp the sleeve to the insulation.

Connections

From my experiences I have found wires rarely fail in the middle of a wire run. Of course the exceptions to the rule here is a nick in the insulation letting in moisture to corrode the wire, chafe due to the lack of securing points, crush damage or perhaps lying against the hot metal of the motor, or heater. So almost all wiring problems occur at the connections.

|

| The screws in this terminal strip are not captive and ring terminals have been used on the wires. |

As discussed in the terminal section, selecting the proper connector requires you to match it to the correct size wire gauge and to the size of the terminal block screw or buss bar stud. I have found ring terminals are your best choice unless the terminal screw is captive, then the best connector to use will be a flanged spade connectors.

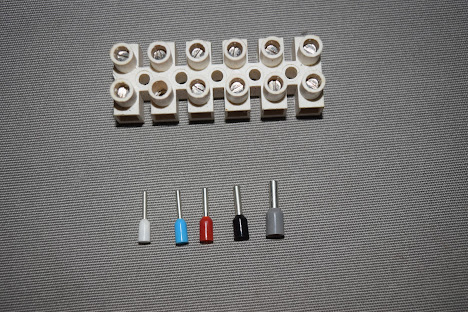

A lot of chandlery’s supply nylon/plastic screw connector strips, while these look like an easy way to make a connection they are nothing but trouble in the long run. The principal is simple, strip the wire put it the terminal hole and tighten the screw down on to the wire. Simply tightening the screw can cut part way through the conductors. This is not to say all of these strips are bad, there are some that have protective shield to stop screw damage but these are hard to get. If you must use these connectors use a crimped pin terminal or ferrule over the wires to protect against damage. But in the long run using terminal block strips with screws and ring terminals on the wire is a more reliable way of making connections.

|

| Screw connector strips. Example of crimp on pin terminal and ferrule used to protect conductors in screw strip terminal |

|

| Terminal Blocks. Fuse Block with ring terminals on wire ends for reliable connection |

You are likely to come across an install where the equipment is supplied with wire leads instead of terminals. A radio for example and having a terminal block would not be convenient for the connection of power, external speakers and perhaps GPS or AIS. Inline connectors let you connect supply wires together easily, there are several sizes in the insulated crimp range, and to aid servicing at a later date it could be a good idea to make the connection with blade or bullet snap connectors instead of the fixed inline connectors/cable joiners.

Here a few no no’s unless it’s a get home type repair, never twist wires together to make a connection, and never wrap a bare wire around a terminal, if you must, put it under a washer and do the screw or nut up. While three-way snap on connectors are useful for tapping into an existing circuit, they are a quick way to introduce corrosion into perfectly good wire. They rely on insulation displacement for contact, then in doing so inevitably nick the tin plating off the conductor. Then the design of the snap on connector will not supply enough of a water block for the marine environment.

Extras

Wire, terminals and bus bars can corrode in the marine environment but the corrosion is accelerated when the damp wiring is able to form an electrical circuit through the fine layer of moisture. Care should be exercised and drip loops put in place to minimize the water becoming a return path for the electrical current.

One thing that is often forgotten during installations is securing the cables. This is to guard against chafe, vibration and in some cases heat and pinch points. What’s a pinch point you ask?? It’s a point where due to some mechanical movement, wire can be trapped in the mechanism or crushed when the machine is in use. Well it could be a locker door a rudder stop an auto pilot arm, cogs in the steering pedestal and so on. As a general rule tying the cables to a secure point every three hundred millimetres is very good and will certainly limit vibration induced cable failure. This may be extended to a greater distance but I wouldn’t go much past five hundred millimetres unless absolutely and entirely necessary.

The wire run should start at a fuse or circuit breaker. The fuse should be sized to protect the wire in the run, this will be a larger size fuse than the appliance or unit requires for protection. Install a fuse to protect the appliance at the unit, this will help reduce the voltage drop and the heat in the circuit breaker/fuse at the beginning of the wire run.

If you must join wire with a crimp connector in the middle of a run, install adhesive lined heat shrink tube or wrap the lot up with self-amalgamating (self-sealing) rubber tape to supply a layer of moisture protection. I have never found liquid electrical insulation to be much good, it doesn’t give much protection, and adhesive lined heat shrink is a good option. Really on a boat to small of cost of adhesive lined shrink tube is worth every additional cent and I now days I only buy the adhesive type. Use rubber tape and shrink tube for a seal as good as the original insulation if done correctly.

What about the screw terminals in my nav lights or other electrical units. The best thing to do is to use a ferrule over the wires before inserting it into the hole under the screw. To add some protection from the elements out there in the weather I dip the ends of the wire into high melt point silicone grease (Molykote 111 or №4) before making the connection and tightening up the screw. I also apply the same grease to the electrical contacts on the bulb to reduce the chance of corrosion.

So to sum up do the job right the first time and save yourself the grief of having unreliable electrics and electronics.

If you don't have the time or money to do it right in the first place, when will you get the time and money to do it over again.

Choosing quality terminal connectors can make a huge difference in durability and safety.

ReplyDelete